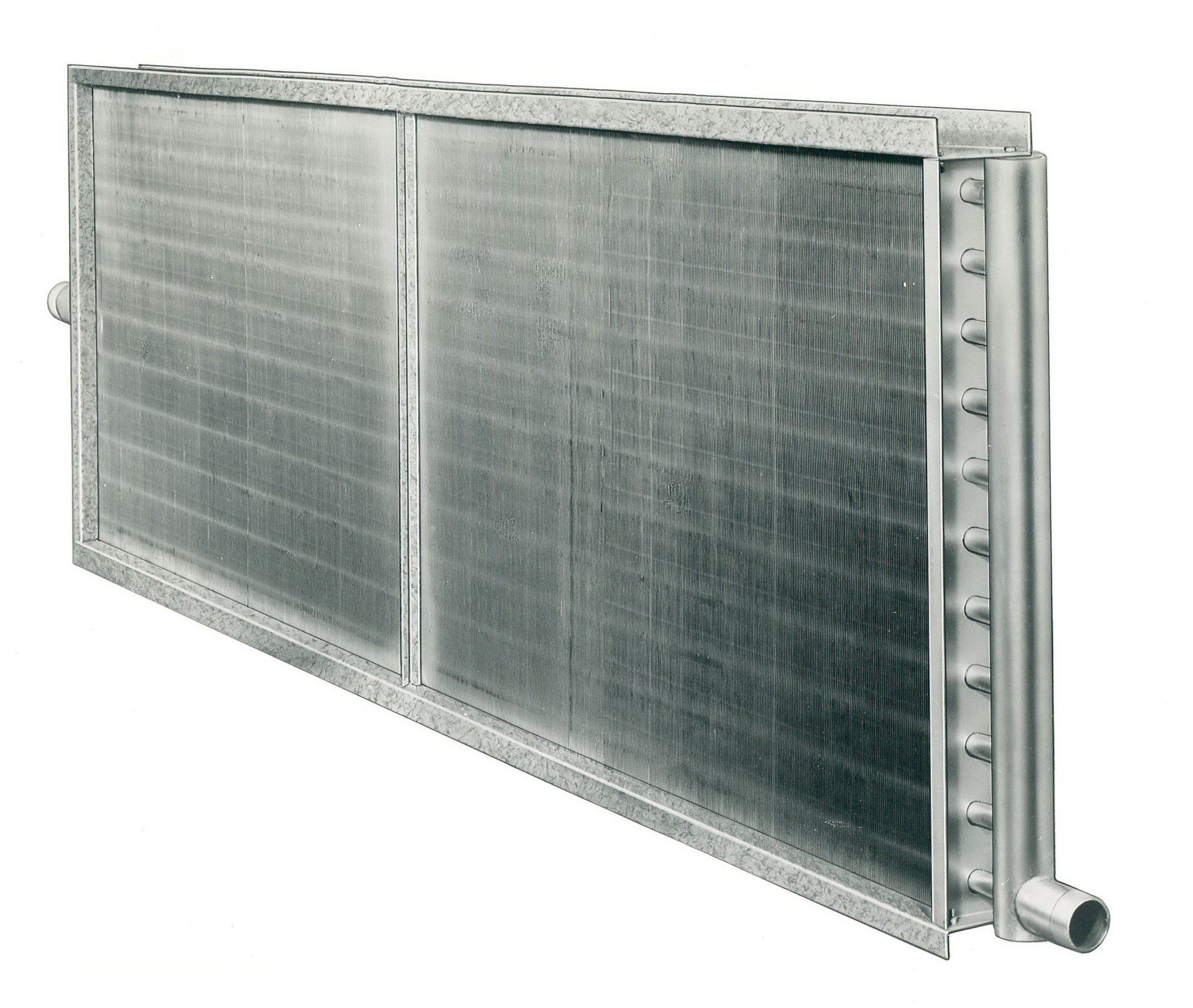

Steam Distributing Coils - SDD

Contact Us

ANDERSON - SNOW Corporation engineers are experienced in solving steam coil problems. Proper drainage, trapping and piping are essential for long coil life. We will gladly assist you with such problems and can fabricate specially designed coils for unusual applications or for the replacement of any existing coil. EXCELLENT CONDENSATE DRAINAGE is provided due to the large area between the inner steam distributing tube and the outer condensing tube, in combination with the pitched tubes.

COIL PERFORMANCE FEATURES

- Uniform coil temperature - minimum air stratification

- Tubes pitched in casing

- Positive condensate drainage

- Plate type fin - minimum dirt clogging

- Vacuum breakers for improved drainage

- Special metals for corrosive condensates

- Baked phenolic coatings for corrosive atmospheres

- Standard coils are guaranteed for working pressures up to 150 PSIG and 366 degrees fahrenheit. Coils are air-tested at 225 PSIG under water.

- Coils for higher pressures can be furnished